Headphone L/R test including Noise Cancel

Intuitive QC test system specially made for testing headphones and earphones (Lab and End-of Line Test)

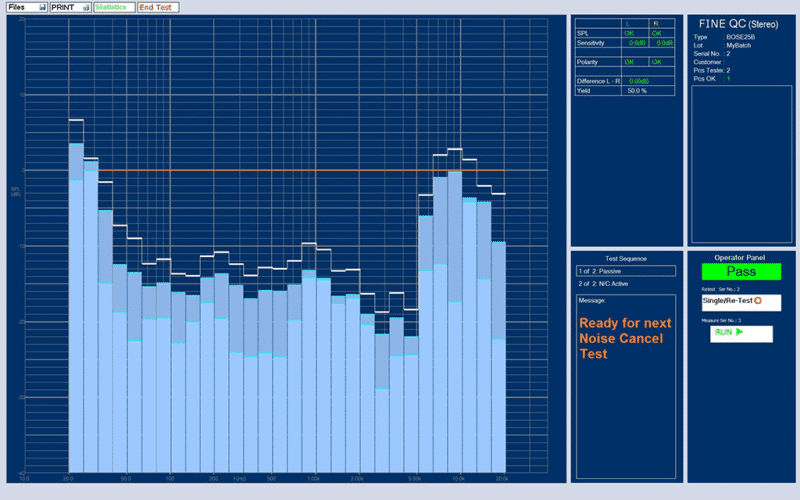

Noise Cancelling headphones (passive and active mode) can be fully tested during the test sequence.

FINE QC includes the best in industry Rub & Buzz method FINEBuzz.

A complete test including L/R Rub & Buzz and Noise Cancel test can be performed in less than 5 seconds.

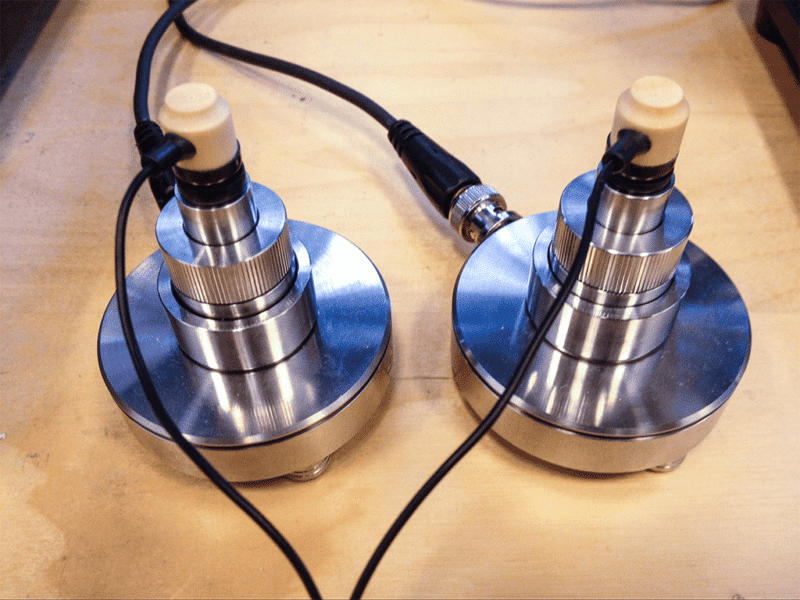

ICP (CCP) microphones connects directly to the hardware 2/3 without separate microphone amplifiers.

“I cannot live without FINE X-over. This wonderful program saves me hours every day”

Alan Shaw, Harbeth

“Fine R+D is the only Test System that is developed precisely for loudspeaker development”

Dolby Audio

Some of our customers

Amazon – B&O – Dolby Audio – Focal –

Harman – Sonos – GGEC – LG – Yamaha

As a consultant Peter Larsen has developed several active and passive Studio monitors, PA speakers, very High SPL speakers, High End speaker systems, Car speakers, Conference speakers, High End Tweeters, Midranges, linear High Xmax Woofers, headphones and much more.

Every project is focused on the client’s needs while designing for smooth production.

Let us help with your new project…..